PROPERTIES OF METALS, STRESS AND STRAIN

IMPORTANT MECHANICAL PROPERTIES

• It is the property by virtue of which a material deformed under the load is

enabled to return to its original dimension when the load is removes.

If body regains Completely its original shape it is called Perfectly elastic body

Elastic limit marks the partial bream down of elasticity beyond which removal of load

result is a degree of Permanent Deformation.

Steel, Aluminium, copper, could also be considered to be perfectly elastic Within Certain Limit.

• Plasticity

The characteristic of the material by which it undergoes inelastic strain beyond those

at the elastic limit is known as plasticity.

This property is especially useful operational of Pressing and Forging.

When large deformation occurs during a Ductile material loaded in plastic region, the

material is said to undergo Plastic Flow.

• Ductility

It is the property which allows a cloth to be drawn out longitudinally to a reduced

section, under the action of tensile force.

A ductile material must possess a high degree of plasticity and strength.

Ductile material must have low degree of elasticity.

This is useful in wire drawing

Brittleness

It is lack of ductility. Brittleness implies that it cannot be drawn out by tension to

smaller section

In brittle material failure happen under load without significant deformation.

Ordinary glass is nearly ideal brittle material.

Cast iron, concrete and ceramic material are brittle material.

• Malleability

It is the property of a material which permits the material to be extended in all

direction without rupture.

A malleable material possess a high degree of plasticity, but not necessarily great

strength.

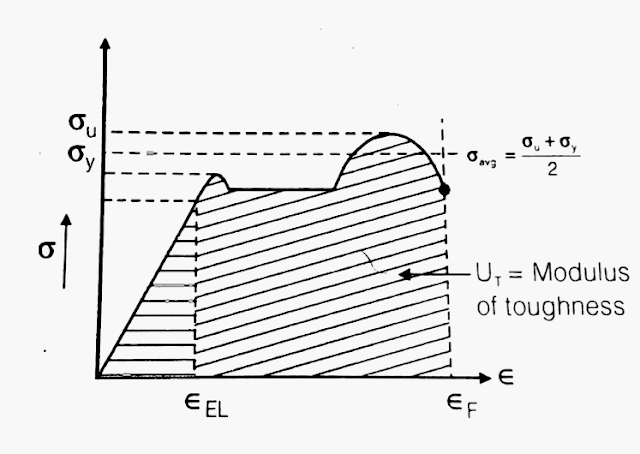

• Toughness

It is the property of fabric which enables it to soak up energy without fracture.

Modulus of toughness UT = (𝜎𝑢+𝜎𝑦)E1/2

It is desirable in material which is subjected to cyclic or shock loading.

It is represented by area under stress – strain curve for material up to fracture.

Bend test used for common comparative test for toughness.

Hardness

It is the ability of a material to resist indentation or surface abrasion.

Brinnell hardness test is used to check hardness.

Brinell hardness number =

Here, P = Standard load

D = Diameter of steel ball(mm)

d = Diameter of indent (mm)

• Strength

This property enables material to resist fracture under load.

This is most important property from design point of view.

Load required to cause fracture, divided by area of test specimen, is termed as

ultimate strength.

• Creep

Creep is a permanent deformation which is recorded with passage of time at constant

loading. it is plastic deformation (permanent and non-recoverable) is nature.

Note: The temperature at which creep is uncontrollable is called

Homologous Temperature.

• Fatigue

Due to cyclic or reverse cyclic loading fracture failure may occur if total accumulated

stain energy exceeds the toughness. Fatigue causes rough fracture surface even in

ductile metals.

• Resilience

It is the total elastic strain energy which can be store in the given volume of metal

and can be released after unloading.

It is equal to area under load deflection curve within elastic limit.

PROPERTIES OF METALS, STRESS AND STRAIN

Reviewed by Digitech education

on

July 16, 2020

Rating:

Reviewed by Digitech education

on

July 16, 2020

Rating:

Reviewed by Digitech education

on

July 16, 2020

Rating:

Reviewed by Digitech education

on

July 16, 2020

Rating:

No comments: